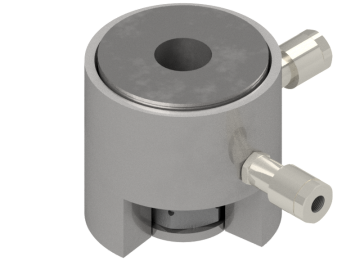

About the product

In order to master the relatively high axial forces required in larger screw connections, it makes sense to use screw tensioning devices. Dunze GmbH has been manufacturing screw tensioning devices very successfully for over 40 years.

Here, the screw is stretched hydraulically with a force that corresponds to the subsequent load plus a safety factor. There is no alternative method to produce screw connections with such precision and with the smallest possible loads for the screw connection. Our bolt tensioners are also a very inexpensive way to handle larger bolted joints.

There is no tightening friction in the thread, which is approx. 80% to 90% with manual tightening, and the setting forces are also significantly lower. A “seizure” of the thread has never been detected so far. Our screw tensioning devices are made of high-strength aluminum and are therefore very light.

The pressure build-up takes place in a ring cylinder. We usually design the required hydraulic pressures for a pressure range of 350 to 600 bar so that inexpensive pumps can be used and the risk of accidents is minimized.

The area of the ring cylinder required for tightening multiplied by the hydraulic pressure plus a safety factor of approx. 10% to 20% corresponds to the inner area of the device to be sealed multiplied by the operating pressure or the test pressure.