We develop and manufacture innovative high-pressure components and systems since 1976.

Due to the relatively small market volume, there are quite few companies in the world who are concerned with high-pressure technology, and still fewer who develop creative and innovative components.

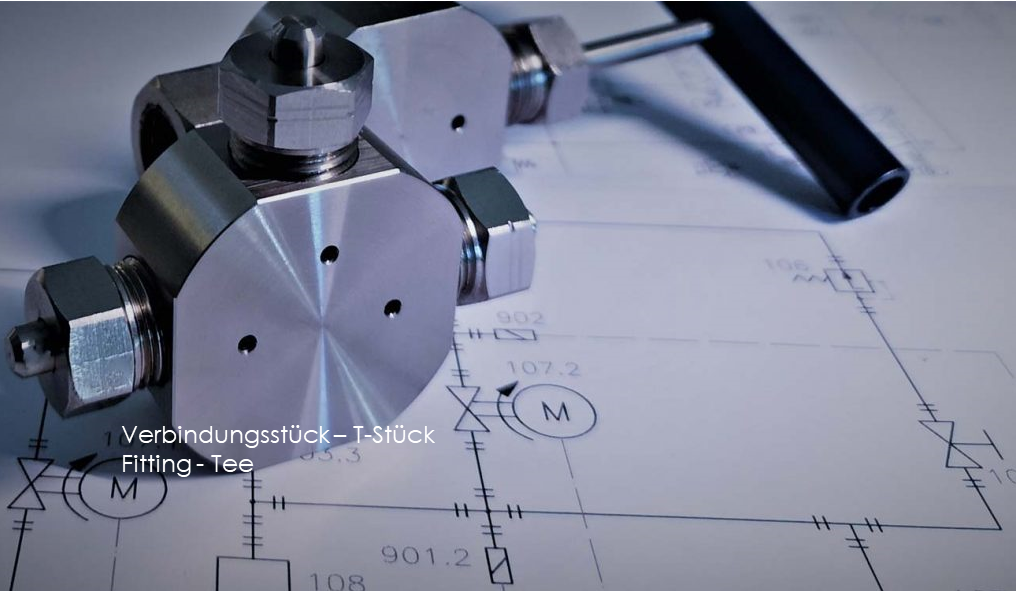

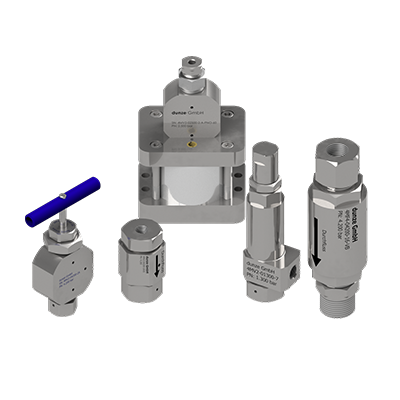

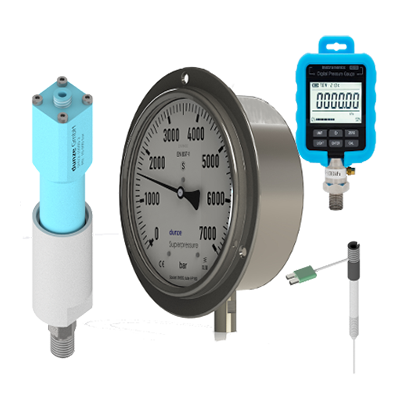

We have developed and manufactured the prototypes or components for almost all new high-pressure systems. In 1985, we were the first company in the world to produce intensifier with a large displacement for hydroforming technology. Even today, our hydroforming check valves are world standard. We are the world leader in valves and fittings. We were the first company in the world to introduce 1.4542 (17–4‑PH) as a standard material for fittings and valves. Likewise, our 120° fitting which is a big increase in quality compared to the 60° fitting. Our product range covers almost all components needed for the construction of small and medium-sized high-pressure plants.

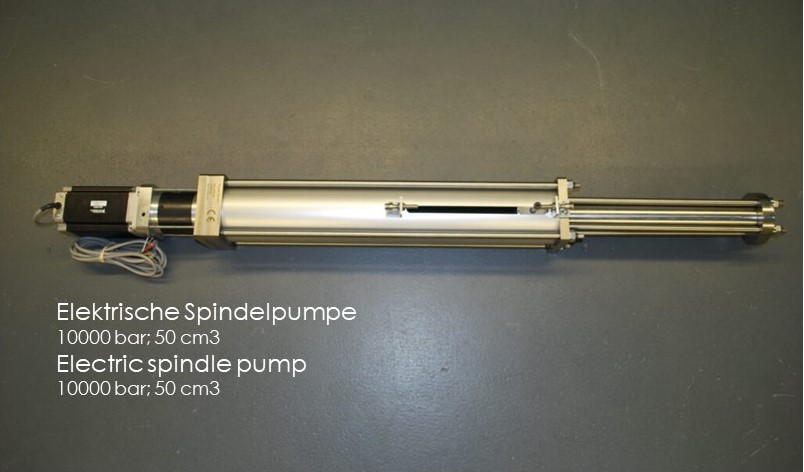

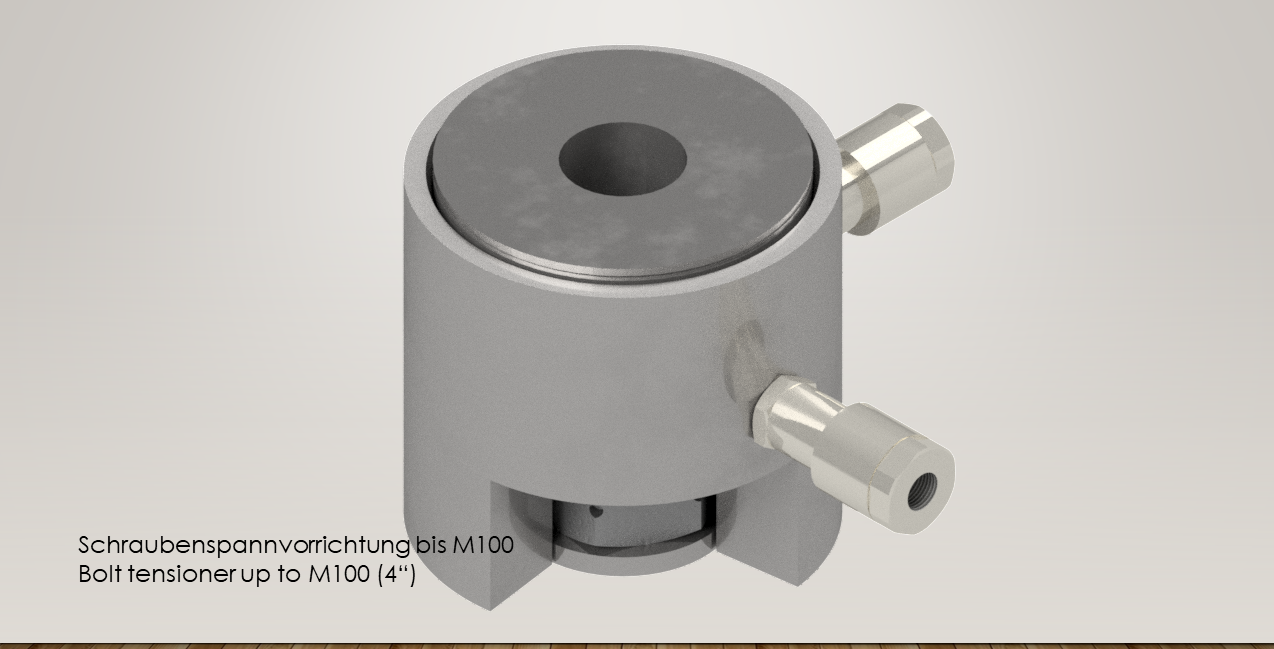

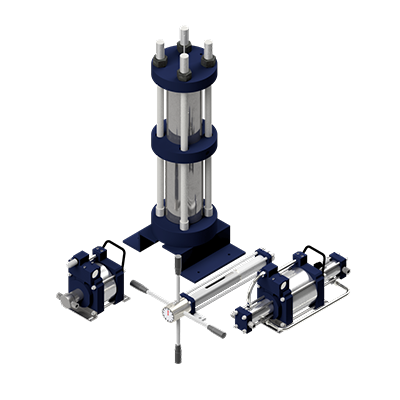

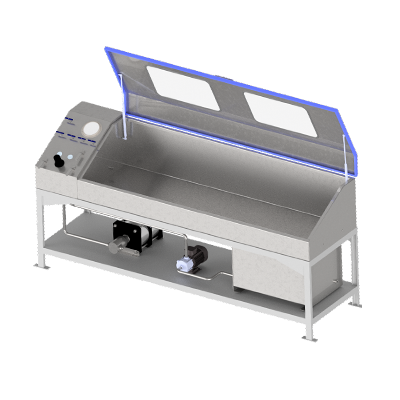

We have a focus in the manufacture of durable components for high-pressure machinery, e.g. Isostatic presses, high-pressure test stands, pasteurization and homogenization plants, bursting pressure test stands and customer-specific high-pressure plants set.

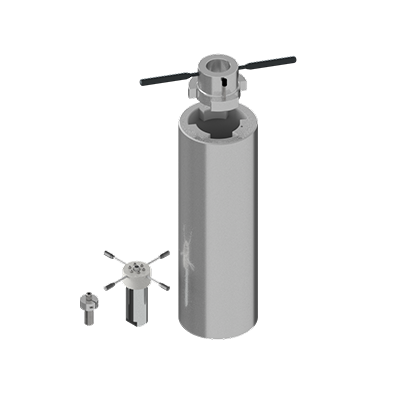

Our autofrettage systems have been running at operating pressures up to 16,000 bars for decades. As part of this activity, a variety of devices have been developed that are tailored to the specific needs of this technology.

As a service we offer pressure test for our customers, autofrettage parts and carry out bursting tests. Since we are very reasonably priced in this area, this is often an alternative to the procurement of own equipment.

We attach great importance to the operational safety of our components and systems. Therefore, we ask for special attention to our safety recommendations.