We offer a wide range of mobile pump units.Please contact us with your request for further information.

We offer a wide range of mobile pump units.Please contact us with your request for further information.

We offer diaphragm compressors for industrail or laboratory applications.

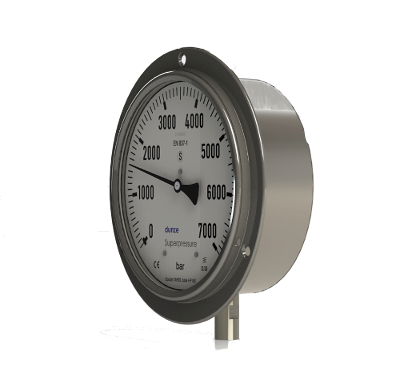

We manufacture our high pressure manometers according to strict specifications. We recommend using pressure gauges for higher pressures only in panel mounting. Normal pressure gauges should not be loaded above 75% of their final value in continuous operation. Pressure gauges filled with liquid are recommended for permanent loads and greater pressure fluctuations.

At higher pressures, the use of a high pressure connection is recommended, as the risk of leakage is considerably lower than with conventional connections. We also build our pressure gauges for higher pressures exclusively with a partition (solid front) and safety glass.

We offer pressure gauges up to 7,000 bar. We use our own pressure transducers for higher pressures.

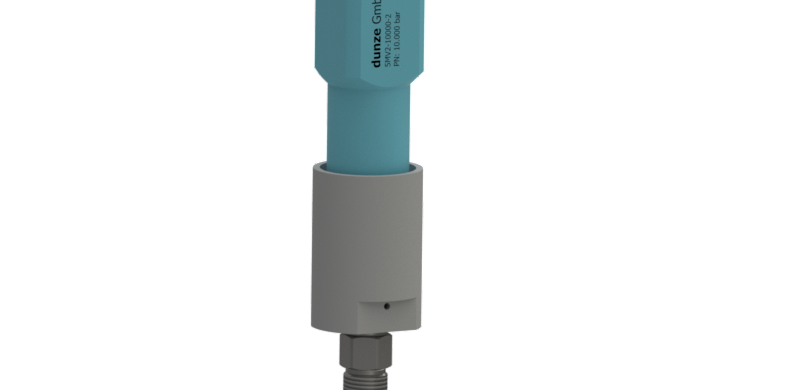

Our pressure transducers have our “short connection” with which they can be connected to high-pressure screw connections in a stable and rotation-free manner. Our pressure transducers are long-term stable and do not have to be replaced every year.

Pressure transducers in all pressure ranges up to 16.000 bar.

The pressure-transmitting medium will usually be a suitable liquid, but in some cases it will also be a gas. Most oils solidify at ambient temperatures above around 2,500 bar and are then unusable as a pressure-transmitting medium. The solidification point can, however, be shifted to higher pressure values by reducing the viscosity, for example by adding petroleum. Water from 20 ° C to 25 ° C is still solid under 9,000 bar to 10,000 bar. At 10 ° C even at 7,500 bar. A high pressure liquid mixture of glycol, water and a rust inhibitor is often used. There are also a number of synthetic fluids on the market which, as a rule, have to be mixed with petroleum or a similar medium for pressures above 7,000 bar. Inert gases can be highly compressed without restrictions. When using oxygen, due to the high risk of explosion when coming into contact with oils, the highest precautionary measures must be taken. The same applies to the use of air and oxygen. When designing a gas system, it is important to know that the compressibility of the gas decreases sharply with increasing pressure. Liquid-like densities are achieved at room temperature even at pressures from 1,000 bar.

We offer you a range of high pressure media for your application.

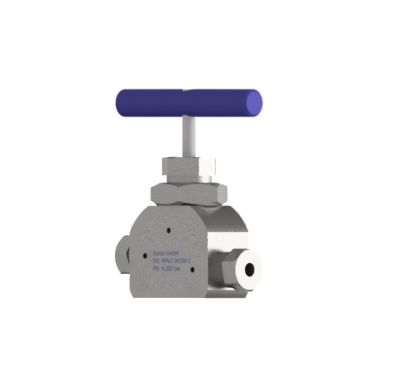

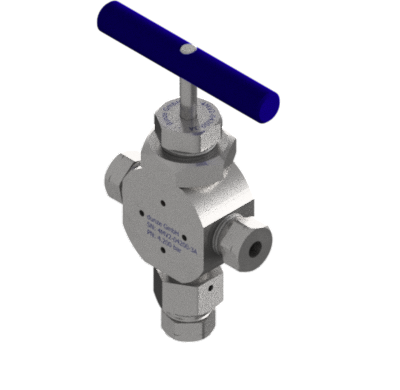

The hand valve has a non-rotating needle, which is pressed into the seat with little wear when it is closed. A fine slope ensures good metering. The panel installation is extremely simple and is achieved by tightening a single nut.

The hand valve has a non-rotating needle, which is pressed into the seat with little wear when it is closed. A fine slope ensures good metering. The panel installation is extremely simple and is achieved by tightening a single nut.

The hand valve has a non-rotating needle, which is pressed into the seat with little wear when it is closed. A fine slope ensures good metering. The panel installation is extremely simple and is achieved by tightening a single nut.

Hoses and fittings

Pressed in our workshop for the shortest delivery times

Whether it is water jets, pressure testing, screw tensioning or just an industrial high-pressure tool, we offer you the right hose. Since we have different sizes of rubber and thermoplastic hoses in stock, we deliver pressed and tested hose lines with the standard connections and accessories for your needs within a few hours. High pressure? No problem. We can offer you hoses up to an operating pressure of 4,000 bar. All hoses are beeing tested before sent.

For special requirements, we can offer you special products such as custom-made fittings, underwater hoses or hoses for well services up to: ID ∅75 mm / 1,034 bar (size ‑48 / 15,000 psi).

We offer pressure and burst tests as a service.

Or we can build a hose testing system for you according to your needs, as a turnkey product.

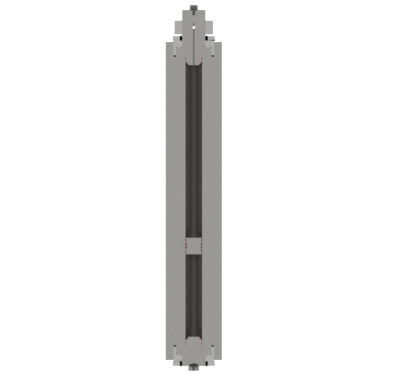

Separator separate two fluids in a cylinder by a piston. On both sides of the cylinder there is the same pressure.

Separator are used when the pressure of a liquid that is easy to pump, e.g. water or hydraulic oil, is to be transferred to a liquid or gas that is difficult to pump.

When transferring to gas, this is often less expensive than a compressor and larger compression ratios can be achieved. Explosive and corrosive gases can be compressed more safely.

Since there is no differential pressure between the two sides of the piston seal, it usually has a long service life.

We manufacture separator in sizes from a few cm³ up to 200 liters and pressures up to 16,000 bar